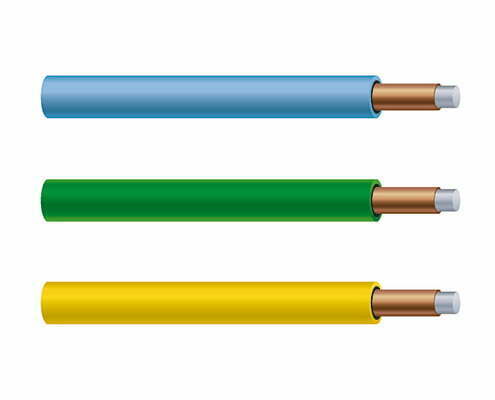

Copper-clad steel tracer wire has become a popular choice in various applications due to its unique performance characteristics. This wire combines the excellent conductivity of copper with the strength of steel, offering a range of benefits.

One significant advantage of copper-clad steel tracer wire is its superior conductivity.

Copper provides excellent electrical performance, which ensures efficient signal transmission. This feature is crucial in applications where minimal signal loss is essential.

Another benefit is the increased strength of the wire.

The steel core gives it enhanced tensile strength, making it suitable for demanding environments. This strength allows the wire to withstand physical stress without breaking or deforming.

Corrosion resistance is also a key advantage.

The copper layer protects the steel core from corrosion, which extends the wire’s lifespan. This feature is particularly important in outdoor and industrial settings where exposure to moisture and chemicals occurs.

Moreover, copper-clad steel tracing wire is lightweight and flexible.

This flexibility simplifies installation and reduces labor costs. Installers can maneuver the wire easily, which improves efficiency and speeds up project completion.

However, challenges exist alongside these advantages.

One challenge is the cost of production. The manufacturing process for copper-clad steel wire can be more expensive than traditional materials. This cost can affect budget-sensitive projects.

Another challenge is the potential for galvanic corrosion.

When copper and steel come into contact with moisture, galvanic corrosion can occur. This issue may compromise the wire’s integrity over time, especially in harsh environments.

Additionally, the performance of copper-clad steel tracer wire can be affected by temperature fluctuations.

Extreme temperatures may cause expansion or contraction, impacting the wire’s functionality. Users must consider these factors when selecting this wire for specific applications.

Despite these challenges, the demand for copper-clad steel tracing wire continues to grow.

Industries recognize its advantages and seek to mitigate the associated risks. Manufacturers are working on improving production techniques to enhance performance and reduce costs.

Research also focuses on developing better protective coatings. These coatings can further enhance corrosion resistance and longevity. Innovations in this area may address some of the existing challenges.

Furthermore, the versatility of copper-clad steel tracing wire makes it suitable for various applications.

It is widely used in telecommunications, oil and gas, and electrical industries. Each sector benefits from the wire’s unique properties, demonstrating its broad appeal.

In conclusion, copper-clad steel tracing wire offers several advantages, including high conductivity, strength, and corrosion resistance. However, challenges such as production costs and potential corrosion issues must be addressed. As technology advances, the performance of this wire will likely improve, making it an even more attractive option for various industries.